Sunday,26-March-2017

miniCNC & 3D printer

EN

Good day folks,

Recently I bought myself 3D printer (da Vinci Mini WiFi) and mini CNC 2418 router / laser all in one.

da Vinci

That is kind of device from the type, you get what you pay for. As build quality - is nice. Although I should put second bearing of the Z axis. Filament - only PLA. because that is my first 3D printer, do not know what to expect. All parts what I print had shrink from the bottom side. That is kind of annoying distortion. If something is straight like plate after print both ends rise. If the object is like cylinder, cube or open type as “bath tub” then is ok. For now I`ve test only clear plastic and if read right in the web, that can cause bigger deformation than the usual single colour. Soon hope to test pure black one.

Software :

- kind of do the job but is so basic. And also you can`t use 3th parity software

- only rotate and zoom the view pane, and if you zoom a lot then you stuck only in partial of the space. That`s it. Why not to add option to move with keys, or to spin it on position you like to see?

- there is no setting for extruder cleaning. Would be really nice to rise the head, to start preheating and will be easy to pull the old filament out or clean it.

- chip locked. Forget about the chinese cheap refill

- really annoying become when there is some new software update. Every few seconds message pop-up asking to update. And you can`t stop it. As bonus, when try to update, the nozzle did not align properly. reinstall and re calibration with the old software an all go smooth again.

Is it good gift for unimportant small prints - yep, can say so.

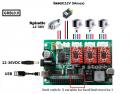

Cnc 2418 + 2.5W laser

Bought that one from aliexpress. Average price. Work.

- it use open source grbl 0.9j firmware.

- software that come with was old , but CANDLE work great with it. Though is far away from Mach 3, it kind of do the job.

- limit switches? To add, use the MDI area of candle and type $$ for firmware options/version. Then find hadrare limits $21 and set it to 1. I use normally open contacts.

- laser - that use simple software and is kind of tricky to guess for what material what sets you need. But still - work.

- also as option, I use molex plug to connect spindle and laser in same spot. It`s simple: left 2 are for laser, right two for spindle and that on the common one. On each cable the pins are only left or right.